|

Introduction on Lift Trucks

Lift trucks are used in a warehouse operation to handle a unit load that includes product sets on a pallet board, on a skid, on a slip sheet, or inside a container. The forks on lift trucks are the chisel type and can adjust to different pallet board, skid, or container fork openings.

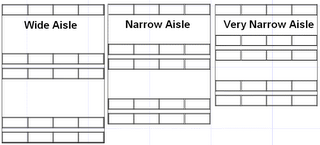

To cater to todays warehouse layout concept, lift trucks are designed and classified into three basic categories and they include Wide-Aisle, Narrow-Aisle, and Very Narrow-Aisle Lift Trucks.

In this section, the objective is to develop an understanding of the various product storage vehicle types. We identify each vehicles power source, type of controls, right-angle stacking width, lift height, throughput capability and captive- versus mobile-aisle ability. In this section, the objective is to develop an understanding of the various product storage vehicle types. We identify each vehicles power source, type of controls, right-angle stacking width, lift height, throughput capability and captive- versus mobile-aisle ability.

- + By World Of MHE + -

Wide-Aisle (WA) Lift Trucks

The first group is the wide aisle lift trucks (vehicles) that operate in 10- to 13-ft-wide aisles. The following 4 examples are WA lift trucks

- + By World Of MHE + -

Walkie Stacker Truck (WA)

A manual push or electric powered drive wheel vehicle Handles a maximum load of 1500lb Up to a stacking height of 10 to 12 ft Receives power from a rechargeable electric battery Costing: USD 2625

- + By World Of MHE + -

Electric-Powered Straddle Walkie Stacker (WA)

Two stabilizing straddles that extend forward from the vehicles base A space between the two straddles for a pallet load Some models are reach types Requires a minimum 6- to 12-ft-wide aisle for a right angle stack or transfer aisle Handles a load weight of 1500- to 3000-lb Up to a stacking height of 10 to 12 ft Slow travel speeds Low through capability Free lift allows the vehicle to operate in a low ceiling area Requires a normal warehouse floor surface Receives power from a rechargeable electric battery Costing: USD 7440

- + By World Of MHE + -

Counterbalanced Walkie Stacker (WA)

- Unique characteristics of a long battery compartment

Long counterbalance weight area Requires a minimum 6- to 12-ft-wide aisle for a right angle stack or transfer aisle Handles a load weight of 1500- to 3000-lb Up to a stacking height of 10 to 12 ft Slow travel speeds Low through capability Free lift allows the vehicle to operate in a low ceiling area Requires a normal warehouse floor surface Receives power from a rechargeable electric battery Costing: USD 8787

- + By World Of MHE + -

Sit-Down Counterbalanced Truck (WA)

Very maneuverable and versatile pallet-handling vehicle Low mast and overhead guard Available with one-, two-, three-, or four-stage masts Used to deposit or withdraw a 2000- to 4000-lb pallet load from a floor stack or specific rack position Up to a stacking height of 16 to 18 ft Requires a normal warehouse floor surface Travels up to 15 degrees grade or ramp Powered by rechargeable electric battery Powered by diesel, LP gas, or gasoline if outdoors Used as a dock, transport, and storage area vehicle Costing: USD 7900

- + By World Of MHE + -

Narrow-Aisle (NA) Lift Trucks

Narrow-aisle vehicles operate in a 7- to 9-ft-wide aisle. The following four examples are NA lift trucks

- + By World Of MHE + -

Stand-up-Rider Straddle Lift Truck (NA)

Designed with two load-carrying wheels and one drive or steering wheel, a set of forks that elevate and lower on a telescopic mast, an overhead guard, stabilizing straddles (outriggers), and an operators platform It does not enter delivery trucks or travel up grades

Operates in a 7- to 8-ft-wide aisle Handles a 2000-lb load Up to a 20-ft-high floor or rack storage position Operators can make 18 to 20 transactions per hour Normal level warehouse concrete floor Powered by a rechargeable electric battery Costing: USD 8500

- + By World Of MHE + -

Straddle Reach Lift Truck (NA)

Operational characteristics to the stand-up-rider straddle lift truck Except that its forks are attached to a pantographic reach device The forks extend out beyond (forward of) the outriggers to pick up and retract a unit load Permits the reach truck to handle a pallet load wider than the interior space between the outriggers Increases the right-angle stack aisle requirement Normal aisle length Up to a stacking height of 8 to 10 ft Operators can make 15 to 18 transactions per hour Costing: USD 12995

- + By World Of MHE + -

Four-Directional Lift Truck (NA)

Similar operational features to the regular trucks Except all wheels turn to the direction of travel One load wheel hydraulically shifts to forward or reverse or lateral for travel (sideways) The other load wheel is the free-swiveling wheel Permits the truck to travel sideway into the narrow storage aisle Normal 8-ft 6-in wide aisle Costing: USD 11500

- + By World Of MHE + -

Stand-Up Two-Deep Lift Truck (NA)

Operational characteristics are the same as those of the straddle reach lift truck Except that the pantographic reach device has a greater extension Extends forward out into the second deep interior pallet rack position of the two-deep rack system For best result, this extension (stroke) is a fixed number of inches (43- or 51-in) This means that all pallet boards must have the same dimension With a 9- to 10-ft-wide aisle Operators can make 13 to 16 transactions per hour The two-deep system does increase the storage density per aisle Costing: USD 8240

- + By World Of MHE + -

Very Narrow-Aisle (VNA) Lift Trucks

It operates in a 5-ft 6-in to 6-ft wide aisle. The following two entries are example of VNA lifts trucks

- + By World Of MHE + -

Sit-Down-Rider Counterbalanced Side Loader with Swing Mast (VNA)

Operational characteristics are the same as for the regular counterbalanced lift truck The telescopic mast swing 90 degrees to the right side of the aisle to make a deposit or withdrawal of goods Operates in a 6- to 8-ft-wide wire-guided aisle with a minimum aisle width which is a nominal 1 ft wider than the pallet load The swing-mast truck makes 3000-lb pallet load transactions from floor or rack positions Up to a stacking height of 25 to 30 ft Operators throughput capability is 17 to 20 pallet loads per hour for a dual cycle When the transactions are not on the same side, then productivity is 15 to 17 transactions per hour because of the need for two down-aisle trips The truck requires a dead-level floor and a 10- to 12-ft intersecting aisle The power source comes from an electric rechargeable battery Able to travel with its forks facing the side of the aisle The swing-mast truck transports long unit loads Costing: USD 13500

- + By World Of MHE + -

Counterbalanced Rising Cab with Auxiliary Mast Lift Truck (VNA)

The unique feature of this truck is the auxiliary mast attached to the front of the cab This multi-mast vehicle carries the pallet load in front of the operators cab As the cab moves up or down, the pallet load on an auxiliary mast moves with the cab Also, in a carton storage or order-pick operation, the operator can hand-stack cartons This feature provides the truck with 60-in of free lift Allows a 2000 to 3000-lb load to be deposited or withdrawn From a 40-ft-high rack position with minimal damage to the product or equipment The truck requires a 16- to 20- clearance from the bottom of the ceiling Compared to other lift trucks, operator productivity is increased by 1 to 2 unit loads per hour Costing: USD 12100

- + By World Of MHE + -

Lift Truck Mast

The second most important lift truck component is the type of mast. There are two mast specification parameters. The first is the overall extended (lift) height that allows the vehicle to deposit or withdraw a unit load from the highest floor or rack storage position. The second is the lowered (down) or collapsed height of the mast. This height is the clearance for the lift truck to pass through the facility doorways, enter delivery trucks, and enter dense storage rack lanes.

Seven types of masts are available for a lift truck:

(i) Single-Stage Non-telescopic Mast -

It lifts a unit load to a 7- to 8-ft-high floor or rack storage position. In today warehouse operation, the single-stage mast has very limited application and is uncommon in a company lift truck fleet.

(ii) Two-Stage Non-telescopic Mast -

It has little or no free lift. No free lift means that as the forks start to rise, the mast starts to rise. With this mast, the lift truck deposits or retrieves pallet loads at storage positions that are 12 to 13 ft high.

(iii) Two-Stage Standard Mast with Low Free Lift -

With this mast, the lift truck deposits and withdraws a unit load from a storage position that is 15 to 20 ft high. This mast feature of low free lift conserves energy and allows the lift truck to be used as a multipurpose vehicle in a warehouse with a low or high ceiling.

(iv) Two-Stage Mast with High Free Lift -

This free lift mast permits the pallet load to be raised to almost half the mast height without elevating the mast. This feature permits the lift truck to operate as a dock vehicle that loads or unloads delivery vehicles. Also the lift truck deposits and retrieves unit loads from storage positions 20 ft high, and it can operate in an area that has a low ceiling.

(v) Three-Stage Mast with Full Free Lift -

The mast feature allows the lift truck to deposit or withdraw unit loads from 20- to 25-ft-high storage positions. Also the full free lift permits the lift truck to operate in facility areas with low ceiling clearance.

(vi) Four-Stage Mast with Full Free Lift -

This mast feature permits the lift truck to deposit or withdraw unit loads from the 30- to 40-ft-high positions.

(vii) Rigid Mast with or without Free Lift -

The rigid mast permits the unit load deposits and withdrawals from an elevated rack position 40 to 60 ft high. The rigid mast is associated with the hybrid or storage/retrieval system vehicles.

- + By World Of MHE + -

Lift Truck Maneuverability

The next most important factor is the lift trucks maneuverability, or ability to make a right-angle stacking turn or a turn in an intersecting aisle.

(i) Right-Angle Stacking Turn

It is the distance required for the lift truck to turn and make a deposit or withdrawal from a storage position The distance is the aisle width Easy way to determine aisle width: take a conventional pallet load length (stringer) plus the distance from the face of the forks to the centreline of the truck drive wheel plus the outside turning radius; if there is unit load overhang, the overhang dimension is added to the stringer length (ii) Lift Truck Wheelbase

It is the distance between the front and rear wheels It determines aisle width Lift Truck with short wheelbase requires a narrow right-angle turning aisle Short wheelbase makes the truck very maneuverable

- + By World Of MHE + -

|